In the realms of science and engineering, precision holds paramount importance across various practices. Among these, metrology, the science of measurement, stands out prominently. A crucial tool within metrology is the surface plate, which is indispensable for organizations requiring impeccably flat surfaces. But what exactly are surface plates?

In this discussion, we delve into their applications, brief historical background, significance in engineering and science, and the characteristics that render them ideal as flat surfaces.

Applications

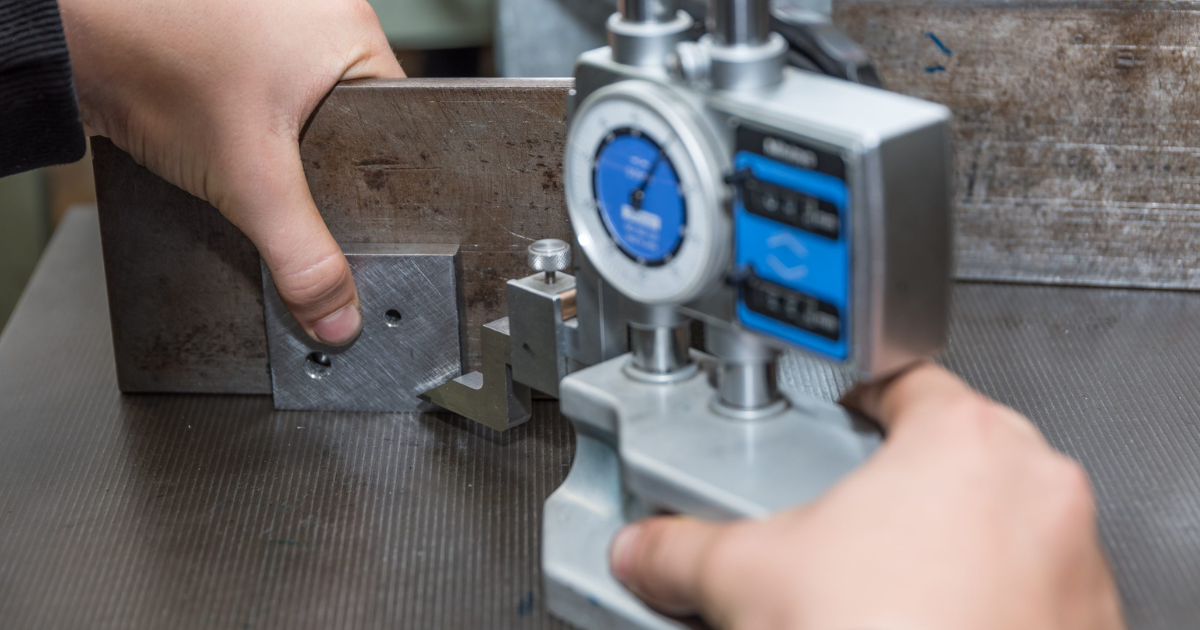

Surface plates find utility wherever precision and accuracy in measurement are imperative. The manufacturing sector, in particular, relies heavily on surface plates during the inspection of products and components. These plates, known for their specific tolerance of flatness, provide a stable foundation for precise measurements such as flatness and squareness. Industries like aerospace, where adherence to stringent specifications and tolerances is paramount, depend on surface plates for construction and testing purposes. Moreover, quality assurance processes often necessitate the use of surface plates for precise measurement and inspection of final products.

Other applications include:

- Precision tool manufacturing

- Marking and layout tasks

- Research and development activities

- Calibration of measuring instruments like height gauges

Historical Perspective

Though Henry Maudsley did not invent surface plates, his recognition of the necessity for standardized flat surfaces was pivotal. Subsequently, Crown Windley, now under Eley Metrology, established industry standards for surface plates and began manufacturing cast-iron variants. While surface plates were predominantly made of iron until World War 2, the shift towards granite occurred due to its favorable properties.

Properties of Surface Plates

Surface plates must possess several key properties to ensure accuracy across diverse operating environments. The chosen material for the plate’s surface must allow for precise flattening within specified tolerances. Smoothness across the surface ensures uniform flatness, while stability is crucial for consistency in measurements. Durability is another essential characteristic, requiring the plate to resist deformation and have a low coefficient of thermal expansion to mitigate changes in flatness due to temperature variations.

Material Composition

While granite remains the preferred material for surface plates due to its durability and resistance to deformation, other materials like cast iron and glass offer distinct advantages and cost considerations.

Accuracy and Calibration

Clients often seek assurances regarding the flatness accuracy of surface plates. Standards such as British Standard BS 817:2008 classify surface plates into grades based on their accuracy, ranging from Grade 0 (most accurate) to Grade 3 (least accurate). Regular calibration is essential to maintain precision, with the frequency depending on usage and environmental factors.

Maintenance and Protection

To preserve flatness between calibrations, proper maintenance and protection measures are crucial. Using the plate only for its intended purpose, employing protective covers, frequent cleaning, and rotating usage areas can help mitigate wear and maintain accuracy.

Accessories

Various accessories like ledges, metal inserts, straps, v-blocks, angle plates, and stands complement surface plates to facilitate precise measurements and ensure user comfort.

Further Information

With a legacy spanning over a century, Eley Metrology, through its Crown Windley brand, offers expertise in surface plate manufacturing. For inquiries and assistance, visitors are encouraged to reach out via the website contact form.

Feel free to explore and purchase these precision tools and equipment on the TMK website to enhance your operations.