Precise measuring instruments are indispensable for metalworking operations in both industrial and commercial settings. Without them, you risk inconsistencies in your product quality. Hardness testers play a crucial role in this regard, enabling you to assess the durability, strength, and toughness of your materials.

There exist various types of hardness testers, each tailored to specific applications and equipped with unique features. In this guide, the experts at Penn Tool Co. outline the seven most prevalent types of metal hardness testing tools.

THE 7 TYPES OF METAL HARDNESS TESTERS AND THEIR USES

1. Brinell Testers

The Brinell hardness tester, pioneered by Swedish engineer Johan August Brinell in 1900, remains one of the oldest and most widely used methods for assessing metal hardness. Renowned for its precision and reliability, it is particularly suited for softer and non-ferrous metals. The Brinell test entails pressing a hardened steel ball into the material’s surface and measuring the resulting indentation.

2. Knoop Testers

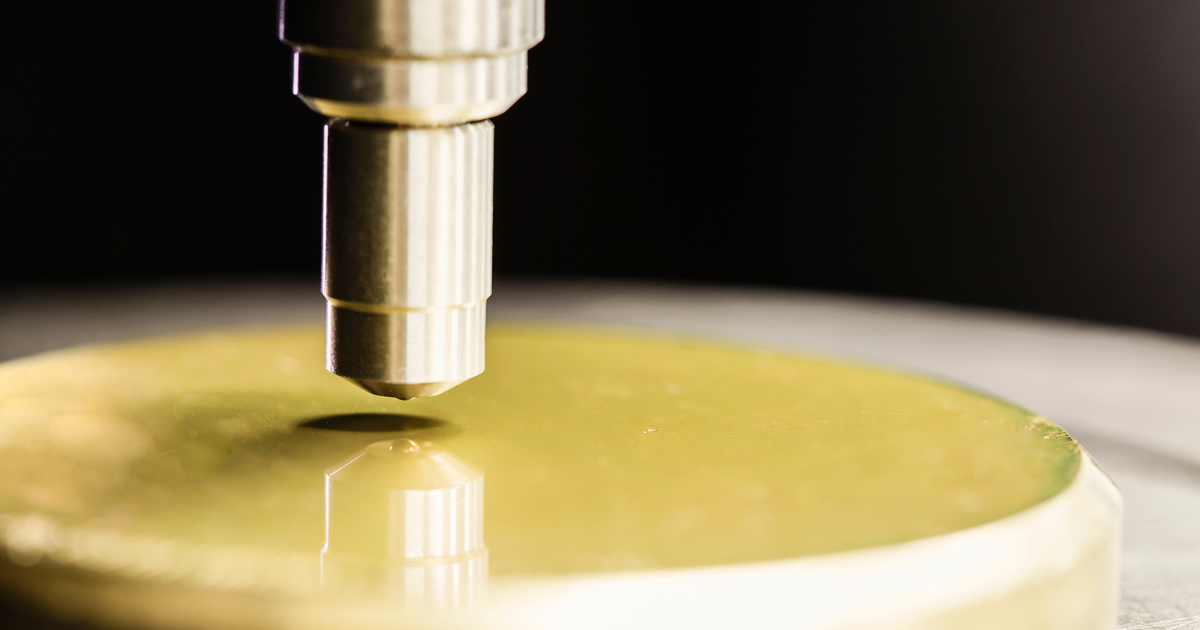

Knoop hardness testers are utilized to determine microhardness, especially in thin coatings and small components. The test involves pressing a diamond tip into the material’s surface, creating a small indentation subsequently measured using a microscope.

3. Leeb Testers

Leeb hardness testers, portable and non-destructive, are ideal for on-site metal hardness measurements. This method involves firing a small tungsten carbide ball at the material’s surface, with hardness determined by measuring the ball’s rebound velocity.

4. Rockwell Testers

Rockwell hardness testers are versatile instruments employed to assess the hardness of metals, plastics, and other materials. The test entails pressing either a diamond cone or a steel ball into the material’s surface, with indentation depth measured using a gauge.

5. Shore Testers

Shore hardness testers, portable devices, are utilized for assessing the hardness of soft materials like rubber, plastics, and foam. The test involves pressing a small indentor into the material’s surface, with hardness determined by measuring the depth of the indentation.

6. Vickers Testers

Vickers hardness testers, employed for microhardness testing, are suitable for small and thin samples. The test involves pressing a diamond pyramid tip into the material’s surface, creating a small indentation measured using a microscope.

7. Webster Testers

Webster hardness testers, portable devices, are designed specifically for measuring the hardness of aluminum alloys. The test involves pressing a hardened steel bar into the material’s surface, with hardness determined by measuring the depth of the indentation.

FIND THE RIGHT HARDNESS TESTERS FOR YOUR SHOP AT TMK TECHNOLOGIES

Selecting the appropriate hardness tester is vital for ensuring the quality and durability of your materials. Each tester type offers unique features and applications, necessitating a comprehensive understanding of their distinctions.

In addition to the tester type, other factors to consider include sample size, material type, and required accuracy level. At TMK Technologies, we provide a wide range of precision measurement equipment, accessories, and replacement parts. Contact our team today to discover the ideal metal hardness testing tools for your shop.